Equality and mutual benefit, mutual cooperation, common development in continuous cooperation.

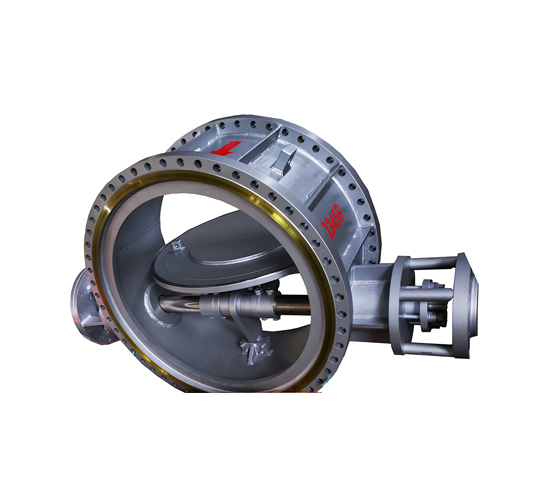

Flue gas butterfly valve

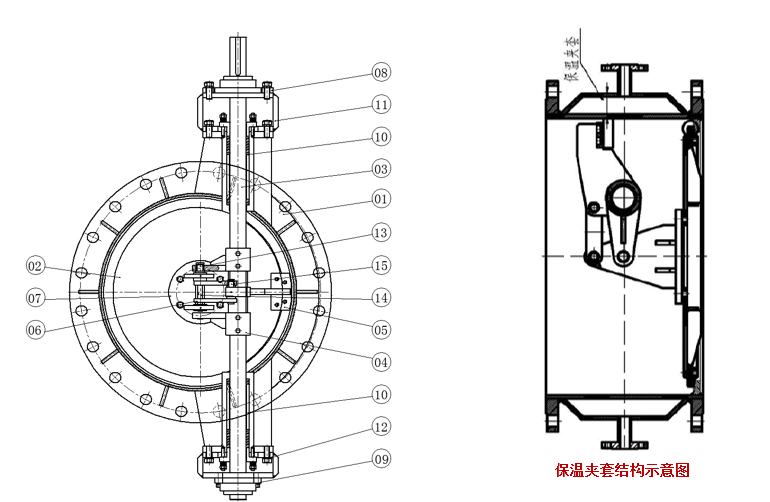

The flue gas butterfly valve is mainly composed of driving device, valve plate, valve body, valve shaft, rod system, shaft end seal and other components. The opening and closing of the valve is realized by the four-bar linkage driven by the valve shaft driven by the driving device. The valve shaft rotates to open the valve plate. When the valve plate is parallel to the center of the pipeline, the valve is fully open; The valve shaft rotates in the opposite direction to close the valve plate. When the valve plate is in parallel contact with the sealing surface of the valve body until the seal is pressed, the valve is completely closed.

155-8887-9032

155-8887-9032

Small friction resistance and light operating torque

a) In the initial stage of opening the valve and the final stage of closing the valve, the valve plate moves parallel to the valve seat, and there is no friction between the valve plate and the valve seat

b) The drive shaft is close to the centerline of the valve, so the drive shaft requires only a small torque

Self cleaning function

The sealing surface of the valve seat is located on the vertical surface, and the solid particles left in the pipeline will not cause damage to the sealing surface of the valve seat during the switching process

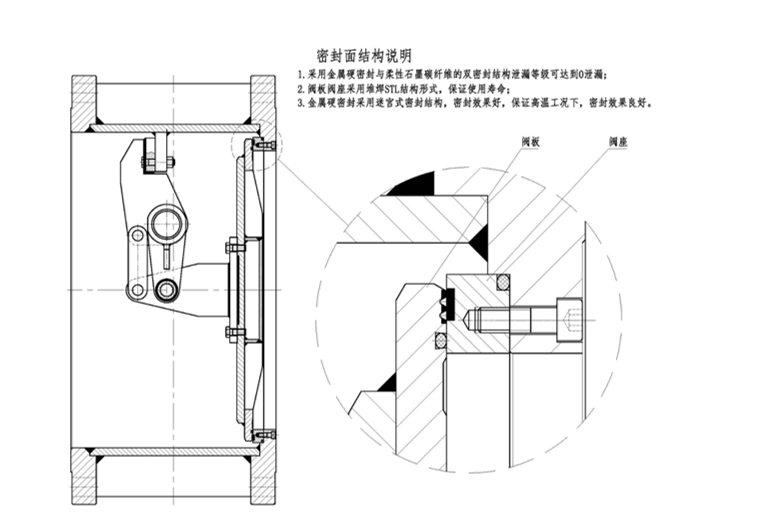

Sealing forms for various applications (multiple combined seats)

a) Soft sealing (P < 7 bar)

b) Metal sealing

c) Double soft sealing with purge gas chamber

d) Metallic and soft sealing

Replaceable valve seat and sealing ring (optional structure)

Reliable structure and long service life

When the valve plate and valve seat are opened, the connecting rod mechanism of the valve limits the maximum pressure difference on both sides of the valve, so as to avoid the impact of high pressure difference and the water in the air inlet, so as to ensure the safety of the system

Stable and reliable operation under high temperature conditions

a) The plane seal ensures that the valve seat and valve plate can be separated immediately without friction resistance under high temperature

b) Under high temperature conditions, the drive rod and guide rod are almost the same length, so as to ensure that the connecting rod system will not get stuck

C) Operating temperature up to 800 ° C

Compact structure design and large flow coefficient

a) Maximum nominal diameter up to dn 4000 (NPS 160 ")

b) The maximum nominal pressure can reach PN 2.0MPa

c) The drive of the valve can be designed according to the requirements of users

(such as electric, pneumatic, hydraulic, manual, etc.)

Zero leakage in accordance with API 598

The plane seal of the valve seat complies with API 598 and can realize one-way seal and zero leakage

Live load packing gland system

Standard low emission valve stem seal with leakage rate of 0-2oppm The live load has predictable and constant packing compression force, which can be operated continuously for 5000 switching cycles without adjusting or replacing the packing.

Various connection forms are optional

a) Double flanged (ASME b16.34-2009) b) butt welded (ASME B16.25)

c) Wafer connection flangeless wafer (API 609)

d) Lug connection single flange - lug type (API 609)

MESSAGE

CONTACT US

-

TEL: 155-8887-9032

-

EMAIL: sales@wtflowcontrol.com

-

ADDRESS:

W&T Asia&Pacific Centre Disclaimer: If some of the information sources on the Internet are infringing or prohibited, please inform us to delete them immediately

Refining and chemica···

Refining and chemica··· Metallurgical indus···

Metallurgical indus··· Gas industry

Gas industry LNG industry

LNG industry Chemical industry

Chemical industry Power industry

Power industry

QQ:664857658

QQ:664857658